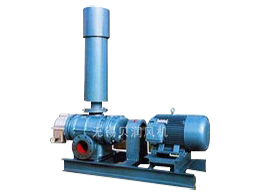

Meltblown Roots blower

Supporting fan for melt-blown cloth production line

Fan type: Roots fan

Pressure range: 9.8-98Kpa

Flow range: 1.25-400m3 / min

Motor power: 1.1-630KW

Transmission mode: direct connection or belt pulley

Features

Melt blown Roots blower has reasonable design, long service life and low noise.

The impeller adopts involute shape to improve the efficiency of the fan; gear grinding processing, grade 5 accuracy; bearings use brand products;

he melt-blown Roots blowers produced by our company have a variety of sealing forms, a variety of transmission methods, a double choice of vertical and horizontal structure, and two impellers with three leaves and two leaves. Each has its own advantages. Optimized selection, stable operation and convenient maintenance.

The working principle and advantages of melt blown Roots blower

1. The melt blower has the hard exhaust characteristics of forced air supply, that is, when the pressure changes, the flow rate change is small. In other words, the pressure can be adjusted "automatically" within the allowable range, while the flow rate change is small.

2. The pressure changes with the change of the system resistance and is adaptive. Roots blower does not have internal compression, how much pressure the system needs. Under the condition that the supporting motor power allows, Roots blower can provide how much pressure, so its pressure is adaptive.

3. The Roots blower has a compact structure, small volume and light weight.

4. Good sealing performance, clean and hygienic delivery media. There is a small gap between the rotors of the Roots blower and between the rotor and the casing and the wall plate. During the high-speed operation of the rotor, there is no contact with each other, so there is no need to lubricate the rotor, so the medium does not contain oil.

5. The Roots fan impeller adopts involute type, with improved sealing performance, high precision of main parts, reasonable structure, reliable operation, stable, low vibration and low noise.

Fan type: Roots fan

Pressure range: 9.8-98Kpa

Flow range: 1.25-400m3 / min

Motor power: 1.1-630KW

Transmission mode: direct connection or belt pulley

Features

Melt blown Roots blower has reasonable design, long service life and low noise.

The impeller adopts involute shape to improve the efficiency of the fan; gear grinding processing, grade 5 accuracy; bearings use brand products;

he melt-blown Roots blowers produced by our company have a variety of sealing forms, a variety of transmission methods, a double choice of vertical and horizontal structure, and two impellers with three leaves and two leaves. Each has its own advantages. Optimized selection, stable operation and convenient maintenance.

The working principle and advantages of melt blown Roots blower

1. The melt blower has the hard exhaust characteristics of forced air supply, that is, when the pressure changes, the flow rate change is small. In other words, the pressure can be adjusted "automatically" within the allowable range, while the flow rate change is small.

2. The pressure changes with the change of the system resistance and is adaptive. Roots blower does not have internal compression, how much pressure the system needs. Under the condition that the supporting motor power allows, Roots blower can provide how much pressure, so its pressure is adaptive.

3. The Roots blower has a compact structure, small volume and light weight.

4. Good sealing performance, clean and hygienic delivery media. There is a small gap between the rotors of the Roots blower and between the rotor and the casing and the wall plate. During the high-speed operation of the rotor, there is no contact with each other, so there is no need to lubricate the rotor, so the medium does not contain oil.

5. The Roots fan impeller adopts involute type, with improved sealing performance, high precision of main parts, reasonable structure, reliable operation, stable, low vibration and low noise.

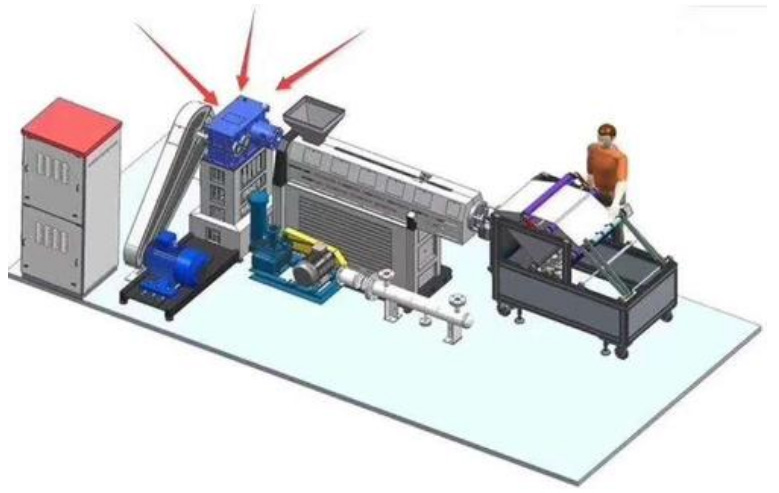

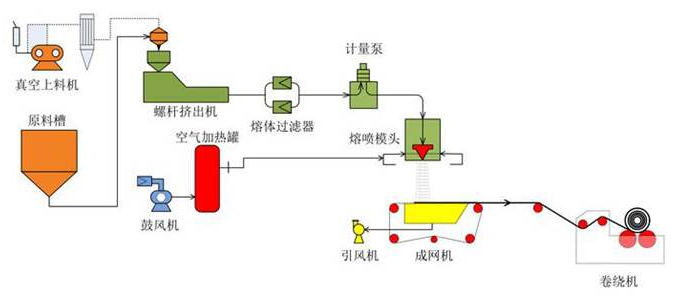

The automatic feeding machine automatically sucks the drawing grade polypropylene into the extruder, and the extruder heats and melts the PP particles to the liquid state. The Roots blower or air compressor and air tank compressed air is sent to the oven for heating, and the hot air is used to force the polypropylene material melted into a liquid to be ejected from the nozzle to form a filament (the nozzle contains hundreds of small holes ) After that, the spun filament reaches the receiving equipment horizontally, and then rolls the non-woven fabric with a roller press.

Process flow

Process flow

Application range of meltblown cloth

Protective suit |

Mask |

Diapers |

Non-woven |